3D Printed Medical Devices are now widely used in the field of implants.

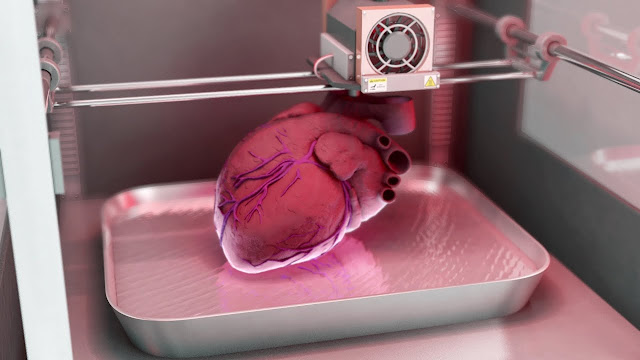

3D printing technology is now widely used in the industry of implanted medical devices. This study examines the manufacturing procedure, materials, and some representative products of 3D-printed implanted medical devices and evaluates and summarises the development trend of 3D-printed implantable medical devices based on the characteristics of 3D printing technology.

In the healthcare

industry, 3D printing, also known as additive manufacturing, is used to produce

a variety of medical items, including orthopedic and cranial implants,

surgical instruments, dental restorations including crowns, and external

prostheses.

Orthopedic and cranial

implants, surgical tools, dental restorations including crowns, and external

prostheses are among the medical items created by 3D printing.

Additive

manufacturing includes 3D

Printed Medical Devices Market. Although there are several kinds of

additive manufacturing, the terms 3D printing and additive manufacturing are

frequently used synonymously. For ease of discussion, both shall be referred to

as 3D printing here.

A three-dimensional

object is produced using the 3D Printed Medical Devices process by adding

successive layers of raw materials. Layers are added one on top of the other

until the object is finished. A digital 3D file, such as a computer-aided

design (CAD) sketch or a magnetic resonance image, is used to create an object

(MRI).

Designers may simply make

adjustments thanks to 3D Printed Medical Devices flexibility

without having to set up additional tools or equipment. Additionally, it

enables manufacturers to design devices with extremely complicated internal

structures or devices that are anatomically tailored to a patient. These

features have greatly increased interest in 3D printing medical devices and

other things, such as food, furniture, and automobile parts.

For decades, from

research and development to production, 3D printing has influenced the

development of novel solutions and medical devices. In order to challenge the

status quo of the healthcare sector, more businesses are obtaining access to 3D

printing as prices for printers drop and investments in hardware and materials

pick up speed.

Medical device designers

and producers can cut costs and market entry time by bringing 3D printing in-house.

The innovation in final-use components, more flexible product development, and

the ability to make tailored medical devices—which are not possible to make

using conventional methods—are all made possible by the technology.

Watch Video 3D Printed Medical Devices Market: https://lumen5.com/user/poonam-165/3d-printed-medical-d-appc3/

Comments

Post a Comment