Petroleum Resins; Low Molecular Weight Thermoplastic Hydrocarbon Resins Used In Various End-Use Industries

Petroleum

resin is a term in common use for low molecular weight thermoplastic hydrocarbon

resins derived from cracked petroleum fractions. These resins are a by-product

of oil refining. Petroleum resins usually have a pacifying effect and are

suitable for use in paints and varnishes, printing ink, coatings, lithographic

inks, adhesives, paper, rubber, concrete-curing compounds, and other areas where

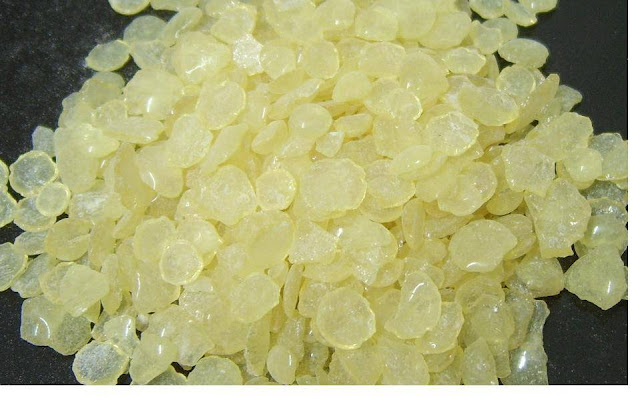

tackiness is required. It is available in the form of a solid block, powder,

crushed nuggets, beads, flakes, solution, and dispersions forms.

Petroleum

resins are a result of crude oil being converted into materials. There are

various kinds of petroleum resins available today. Some of the common

components in petroleum jelly and marbles are PABA (Para-Bates Acetate),

methylated spirits, paraffin wax, mineral oil, calcium silicates, and more.

These resins are very useful for many industrial applications apart from oil

refineries and plastics. They are used in end-use industries, such as construction,

automotive, and consumer goods, among others.

Moreover, there is an

increasing demand for Petroleum

Resins Market containing low

volatile organic compounds (VOCs) due to stringent government regulations on

VOCs emissions. VOCs from vehicles are a significant contributor to Mexico's

pollution, as the precursor to ambient ozone and secondary particulate matter. VOCs

from gasoline evaporation was determined in Mexico to know the emission of each

compound to the atmosphere. Mexico has implemented a number of LMPs for fixed

source emissions from specific industries.

Since

petroleum resins are safe to use, they are widely used in various end-use

industries for a number of applications. In addition, they are also used for

surface coating in petroleum-based fluids such as hydraulic fluid, diesel fuel,

transmission fluid, and water used for dishwashing and cleaning. Petroleum

Resins are preferred over other materials and inks because they have excellent

water resistance properties, which make them usable even in extreme

temperatures, extreme pressures, and high humidity conditions. Therefore, there

is an increase in demand for petroleum resins across the world.

Comments

Post a Comment