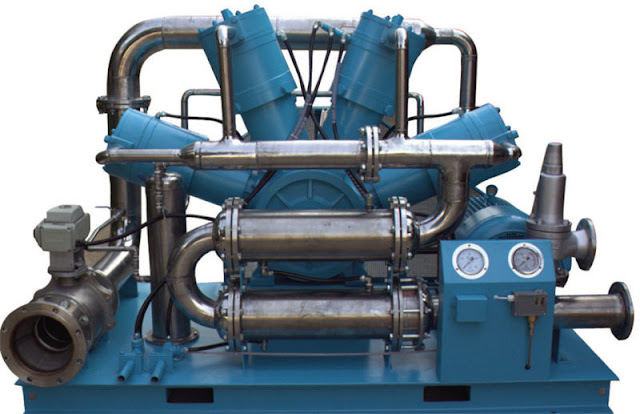

Compressors called booster compressors are designed to increase the pressure of a system

|

| Booster Compressor |

In order to increase the pressure that is discharged from the compressor system through additional compression stages, a booster compressor method is a device that is used. The booster compressors are enhanced by their high pressure capability, production, small size, low noise, installation, and dependability.

A booster system is a

piece of machinery used to boost or amplify air pressure from an existing

compression system by putting it through extra compression stages. With the use

of booster air compressors, air pressures that now range from 80 to 150 PSIG

can be increased to 2000 psig.

A

Booster

Compressor Market is

a piece of machinery that amplifies or increases the air pressure that is

produced by an existing compression system by putting it through extra

compression stages. Air pressures between 80 and 150 psig can be increased to

2000 psig by booster air compressors.

One of the most

affordable methods for obtaining the higher process gas pressures needed at

industrial plants is the use of a compressed air flow booster.

The basic idea behind the

operation of a booster air compressor or compressed air pressure amplifier is

that pressure rises as volume falls in a closed system (other than a vacuum). A

receiver tank, piping, and a discharge tank are all parts of an air booster

compression system.

A compressor called a Booster Compressor is

designed to increase a system's pressure, generally by four to six times the

pressure that machines in factories typically create. Due to the difficulty and

expense of maintaining such high pressure, most factories that require a Booster Compressor only

utilise it temporarily. While this can be used to operate a gadget, testing are

the most frequent usage for it. The majority of these compressors are

pneumatic, or run on air, although a few are also powered by other sources.

Comments

Post a Comment